Creating Pathways for Career Advancement in HVAC

Welcome to the thriving world of HVAC, where career advancement opportunities are as dynamic as the industry itself. With employment projected to grow by 5–9% from 2021 to 2033, the HVAC field is adding thousands of jobs annually, outpacing many other professions. Whether you’re just starting out or looking to climb the ladder, this guide will help you navigate the pathways for career growth and advancement in the HVAC sector.

Understanding the HVAC Job Market

The HVAC industry offers robust job stability, driven by climate change, advanced construction needs, and a skilled labor shortage. The risk of automation is low, making HVAC a hands-on field where expertise truly matters. As of 2025, the median hourly pay for HVAC service technicians is $23.36, with a national average closer to $29.62 per hour, or about $61,600 annually. Entry-level positions start around $54,100 per year, while seasoned technicians can earn between $77,200 and $90,800, depending on location and specialization.

Key Pathways for HVAC Career Advancement

Charting your course in the HVAC industry involves strategic decisions and continuous learning. Here are some key pathways to consider:

- Obtain essential certifications like EPA 608 and NATE to enhance your credentials and marketability.

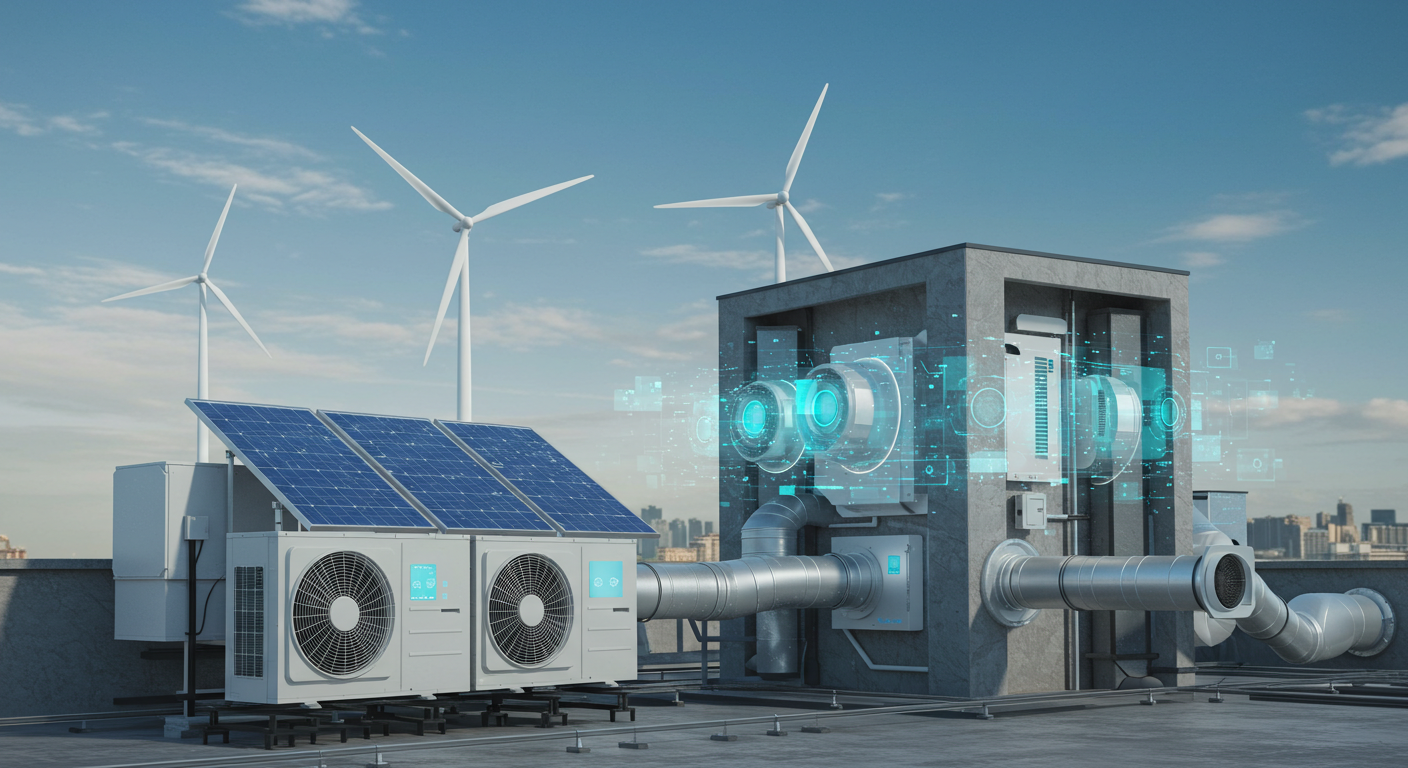

- Specialize in high-demand areas such as refrigeration or renewable/solar-powered HVAC, where expertise is highly valued.

- Gain experience in supervising or managing teams, as HVAC supervisors can earn approximately $90,800 annually.

- Network through industry groups like ASHRAE and pursue continuing education to stay competitive in an evolving market.

- Develop skills in energy-efficient systems and smart HVAC technologies, as offered by Daikin, to command higher salaries.

Maximizing Your HVAC Skills and Opportunities

With 74% of HVAC technicians working for private companies and the rest in public or institutional settings, the industry offers diverse employment opportunities. The persistent labor shortage and retiring workforce mean there’s ample room for upward mobility. Technicians can transition into business ownership, supervisory roles, or niche market expertise for further career growth.

Investing in Professional Development

Continuing education and professional development are key to staying relevant in the HVAC industry. By leveraging HVAC apprenticeship opportunities and certification programs, you can enhance your skills and increase your chances for advancement.

Conclusion

The HVAC industry is ripe with opportunities for those willing to invest in their education and skills. By focusing on certification, specialization, and continuous learning, you can carve out a rewarding career path. Whether you’re aiming for a leadership role or exploring niche markets, the possibilities are endless.

Ready to take the next step in your HVAC career? Start by exploring certification programs and networking opportunities today!

Frequently Asked Questions

What is the projected growth rate for HVAC employment?

The HVAC industry is projected to grow between 5–9% from 2021 to 2033, adding thousands of jobs annually, which outpaces many other professions.

What are the average earnings for HVAC technicians in 2025?

In 2025, the median hourly pay for HVAC service technicians is $23.36, with a national average of approximately $29.62 per hour or about $61,600 annually. Entry-level positions earn around $54,100, and senior technicians can earn between $77,200 and $90,800.

Which certifications are crucial for HVAC career advancement?

Key certifications for advancing in the HVAC field include EPA 608 and NATE. These credentials enhance your qualifications and marketability.

How can I specialize in high-demand HVAC fields?

Consider focusing on areas like refrigeration or renewable/solar-powered HVAC systems. Specializations in energy-efficient systems and smart HVAC technologies are also highly valued.

What are the benefits of networking in the HVAC industry?

Networking through industry groups like ASHRAE and participating in continuing education helps you stay competitive and informed about industry trends and opportunities.