HVAC Leak Detection Tools: Finding and Fixing Problems Quickly

Welcome to the future of HVAC maintenance in 2025! If you’re in the HVAC industry, you know that refrigerant leaks are more than just a nuisance—they can lead to significant performance drops, higher energy bills, and even legal headaches. Don’t worry, though; with the right tools and methods, you can detect and fix these leaks swiftly and efficiently.

Understanding HVAC Leak Detection Methods

There are several tried-and-true methods for detecting leaks in HVAC systems. From classic techniques to cutting-edge technologies, here’s what you need to know:

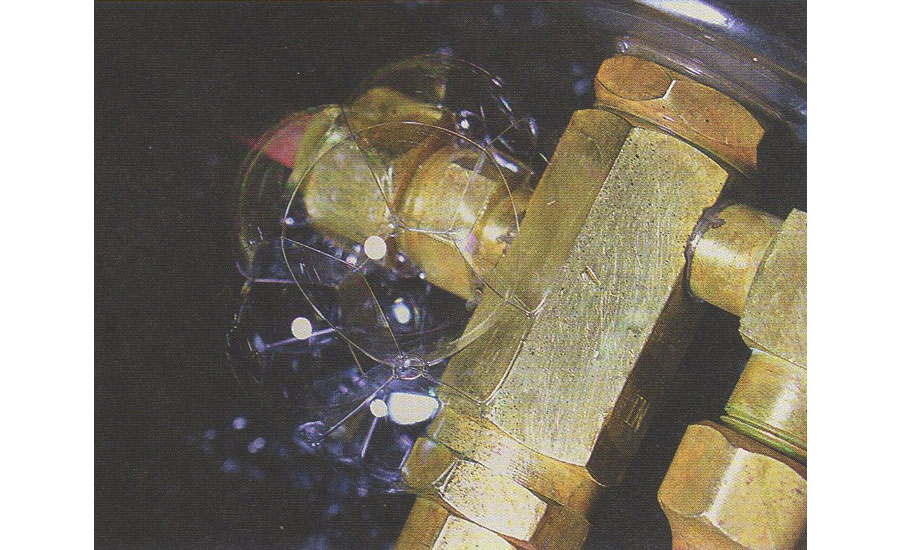

Soap Bubble Method

This is the most affordable and straightforward method. Simply apply a soap solution to suspected leak areas and watch for bubbles. However, this technique might miss smaller leaks or be less effective in windy conditions. Combining it with electronic or dye methods can enhance accuracy.

Ultraviolet/Fluorescent Dye Method

An effective way to visualize leaks, this method involves adding a fluorescent dye to the system that glows under UV light. While effective, it can be messy and might affect long-term system performance if residues persist.

High-Tech Leak Detection Tools

Advancements in technology have introduced more sophisticated tools that make leak detection a breeze. Let’s dive into some of these innovative options.

Electronic and Ultrasonic Leak Detectors

Electronic HVAC leak detectors are designed to pick up even the smallest leaks by sensing changes in the system’s refrigerant levels. Ultrasonic leak detection in HVAC systems uses sound waves to detect leaks, offering a highly sensitive and accurate method of pinpointing issues.

Pressure-Based Testing

Nitrogen pressure testing is another reliable method, using pressurized nitrogen to detect leaks by observing pressure drops over time. This method is especially useful for identifying leaks in complex systems.

- Variable Refrigerant Flow (VRF) systems now boast detection sensitivity improvements of up to 30% over traditional methods.

- Indirect leak detection technologies can identify leaks up to 60 days earlier, reducing refrigerant losses by 80%.

Preventing Future Leaks

Prevention is always better than cure. Using weatherproof refrigerant line seals can protect vulnerable joints and connections. Routine leak checks, along with advanced tools like the Ruud Econet 800 Series smart thermostat, can help monitor and alert you to potential issues before they become costly problems.

Conclusion

Staying ahead in the HVAC industry means embracing the latest in leak detection technology. By understanding the tools and methods available, you can ensure your systems run efficiently and effectively, saving both time and money. Don’t let leaks catch you off guard—be proactive and stay informed.

Ready to upgrade your leak detection arsenal? Visit Mar-Hy Distributors for the latest in HVAC leak repair tools and more!

FAQs

What are the best HVAC leak detection tools?

The best tools include electronic HVAC leak detectors, ultrasonic detection devices, and pressure-based testing kits for accuracy and reliability.

How does an ultrasonic leak detection HVAC system work?

Ultrasonic leak detection uses sound waves to detect the high-frequency sound of a leak, allowing for precise identification of problem areas.

Can the fluorescent dye method affect my HVAC system?

While effective, the dye method can leave residues that might impact long-term system performance if not properly cleaned.

How do I prevent future HVAC refrigerant leaks?

Use weatherproof refrigerant line seals and perform routine checks. Advanced monitoring tools like smart thermostats can also alert you to potential issues.

Why is it important to combine leak detection methods?

Combining methods increases accuracy and ensures even small, hard-to-detect leaks are identified, preventing costly energy losses and repairs.